ASME RAM-2-2016 pdf download

ASME RAM-2-2016 pdf download.Reliability, Availability, and Maintainability Program Development

Process for Existing Power Plants.

The RAM program shall address plant maintainability for the following areas:

(a) access — ease of access to work locations and the ability to work safely without special rigging and tools; assurance that workers have access to equipment that may need service, i.e., equipment is designed so that workers can open, remove, or enter it, and perform other activities

(b) laydown — availability of space to disassemble and store major components such as turbines, compressors, valves, and pumps, and provisions for disassembly and servicing of large equipment

(c) tools — need for special tools and tooling, and assurance that special tools are available ahead of work, or available through contracts

(d) training — availability and execution of specialized training to support scheduled activity and condition- directed work, and assurance that workers are adequately trained to do the work

(e) tagouts — predeveloped tagouts for anticipated work

(I) spare parts — establishment of a spares strategy that ensures availability of spare parts for specialized and other equipment, and that documents sources of emergency spares

(g) contracts and contingency parts — predeveloprnent of standard contracts for work

(h) maintenance plans — predeveloped plans for anticipated, scheduled, and condition-based maintenance; determination of the work the plant personnel can reasonably be expected to do

(I) diagnostics — diagnostics capabilities are known for failure modes

U) rebuild — overhaul instructions and support are known and available by contract

The RAM program should have a comprehensive list of all plant equipment that identifies the expected service life of each plant component. This list of equipment assists in anti simplifies maintainability planning. By developing a RAM program, plant owners can explore maintainability issues before construction begins. As plant physical construction proceeds, the ability to inexpensively address maintainability declines. The RAM program shall include equipment wear-out and aging information. This information shall be used to develop effective maintenance plans that prevent critical equipment aging failures and that avoid unanticipated but foreseeable high costs from deferring recognized, predictable work

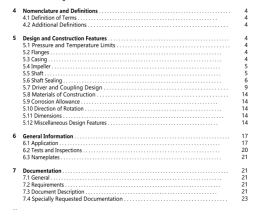

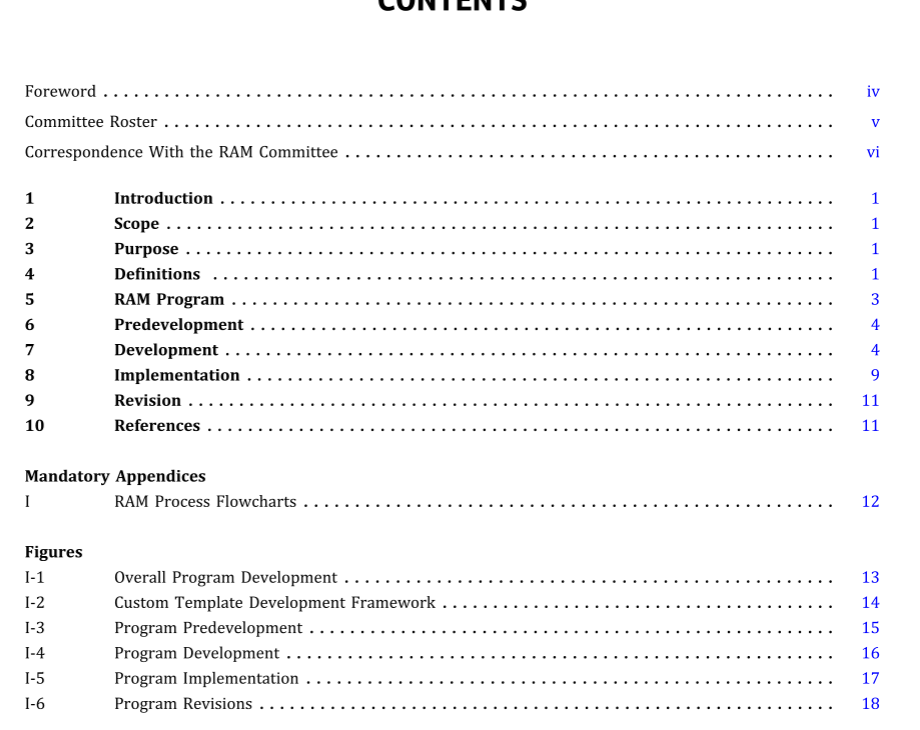

5.3 RAM Process Overview

The following is a summary of the RAM process, which is included in ASME RAM-i:

Step 1. Predevelopment

(a) Establish clear owner requirements as well as goals for reliability, availability, and maintainability of all critical systems.

(b) Establish the scope of the RAM program.

Step 2. Program Development

(a) Develop the MEL, utilizing a universal tagging classification.

(b) Define and assign equipment criticality based on risk.

(c) Develop the critical equipment list based on the following factors:

(1) component type and subtypes

(2) risk and service environment and use contexts

(3) replication of tags for components with similar contexts

(4) use ofan efficient template application process

(d) Compare component templates; the prioritized MEL and systems descriptions enable this step. Replicate equipment in identical contexts.

Step 3. Implementation

(a) Develop the scope of work to do the tasks listed in work orders.

(b) Organize the tasks in Step 2 into structured work order plans (rounds and routes) by the conditions (i.e., the state of the equipment), tagout, and skill required to perform the work.

(c) Load the work scope that results from (a) and (b) into work control systems, principally EAMS and personal digital assistant (PDA) rounds, to finish work development.

Step 4. Revision

(a) Develop performance and exception reports.

(b) Review critical trends.

(c) Review, assess, and adjust the RAM plan accordingly.

(d) Based on experience (i.e., lessons learned), update work scopes and their tasks with changes, such as new equipment.

(e) Query personnel, and use the diagnostics to answer any questions.

jJ) Efficiently structure work for the craftspcoplc by tagout, tools, skills, and other classifications.

(g) Present background material for use, and apply analysis and its results.

6 PREDEVELOPMENT.