ASME B16.15-2006 pdf download

ASME B16.15-2006 pdf download.Cast Copper Alloy Threaded Fittings Classes 125 and 250.

6 ThREADING

6.1 Types of Threads

All pipe fittings shall be threaded with ANSI! ASME 81.20.1 general purpose pipe threads and shall have taper threads, except wrought couplings (Tables 2 and 1-2), wrought caps (Tables 3 and 1-3), and wrought bushings (Tables 4 and 1-4) in NPS 5, NI’S 3 NI’S and NI’S which may have straight internal threads

6.2 Tolerances

The permissible tolerance in taper threading shall be limited to one turn large or one turn small from the gaging face on ring and gaging notch on plug, when using working gages. The variations in straight threading shall be limited to one and one-half turns large or small from gaging notch on plug, when using taper pipe thread working gage. The reference point for gaging internal fittings threads depends upon the chamfer diameter. When the internal chamfer diameter exceeds the major diameter of the internal thread, the reference point is the last thread scratch on the chamfer cone. When the internal chamfer diameter does not exceed the major diameter of the internal thread, the reference point is the end of the fitting.

6.3 Countersink or Chamfer

All internal threads shall not be countersunk a distance of less than one-half the pitch of the thread at an angle of approximately 45 deg with the axis of the thread, and all external threads shall be chamfered at an angle of 30 deg to 45 deg with the axis, both for the purpose of easier entrance in making a joint, and for protection of the thread. Countersinking and chamfering shall be concentric with the threads.

6.4 Length of Thread

The length of threads specified in all tables shall be measured to include the countersink or chamfer.

6.5 Alignment

The maximum allowable variation in the alignment of threads of all openings of threaded pipe fittings shall be 1 mm/rn (0.06 in./ft) or 0.5%.

6.6 Bushings

All bushings shall be threaded with American National Standard taper pipe threads, except those sizes of wrought bushings listed in para. 6.1 which ma’ have straight internal threads. Gaging of all threads shall comply with ANSI/ASME B1.20.1 except those sizes of outside bushings where the external thread lengths are shorter than required by ANSI/ASME B1.20.1. These bushings should be threaded so that when making up the joint, the shoulder of the head will not interfere. To ensure this, the threads, when made to the minimum Cast pipe fittings shall be furnished with a rough exterior surface, free of sand inclusions, fins, and gate protrusions.

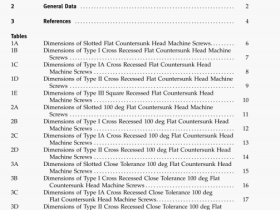

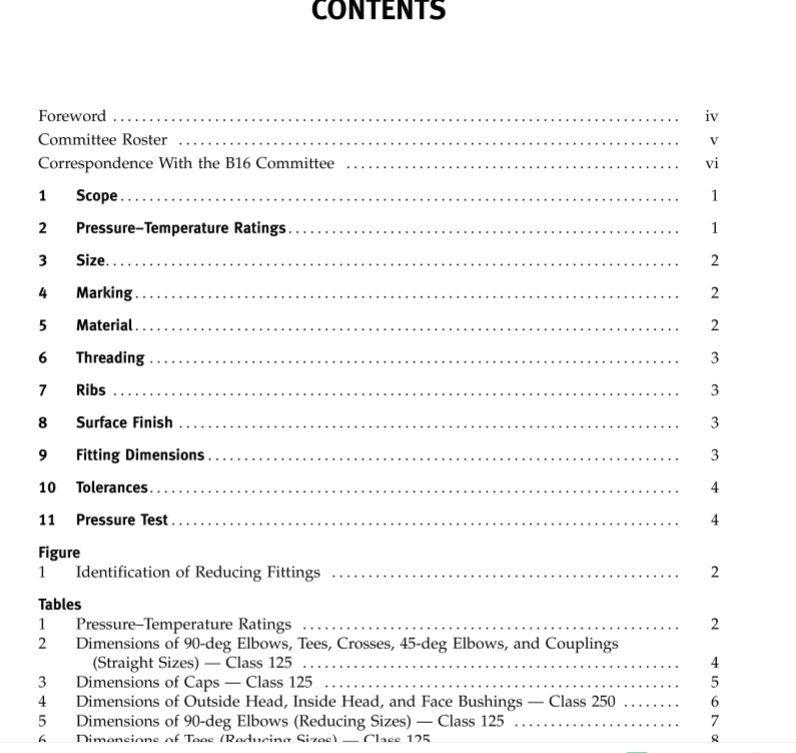

9 FIniNG DIMENSIONS

(a) Tables of center-to-end dimensions are given for both straight and reducing pipe fittings. Dimensions and tolerances shown as whole or multiples of 0.5 mm may differ slightly in absolute value from the corresponding dimensions in Mandatory Appendix I. Any dimension that is within tolerance by either SI or Customary measurement is considered to be in conformance with this Standard.

(b) The dimensions shown in Tables 5, 6, 7, 8, and 9 (Tables 1-5, 1-6, 1-7, 1-8, and 1-9) for fittings are for use only when making patterns for the specific reducing pipe fitting in question and do not apply when a larger size pattern is bushed to make the reducing pipe fitting wanted. Reducing pipe fitting patterns shall be designed to produce wall thicknesses and detail and dimensions as required for the sizes involved.

(c) The sketches of fittings accompanying Tables 2 through 12 (Tables 1-2 through 1-12) arc representative and are included for the purpose of illustration.

10 TOLERANCES

10.1 MetaL Thickness

Dimensional variations are unavoidable in the casting process. Patterns shall be designed to produce castings.