ASME B30.9-2006 pdf download

ASME B30.9-2006 pdf download.Slings.

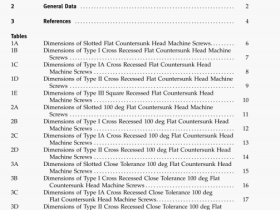

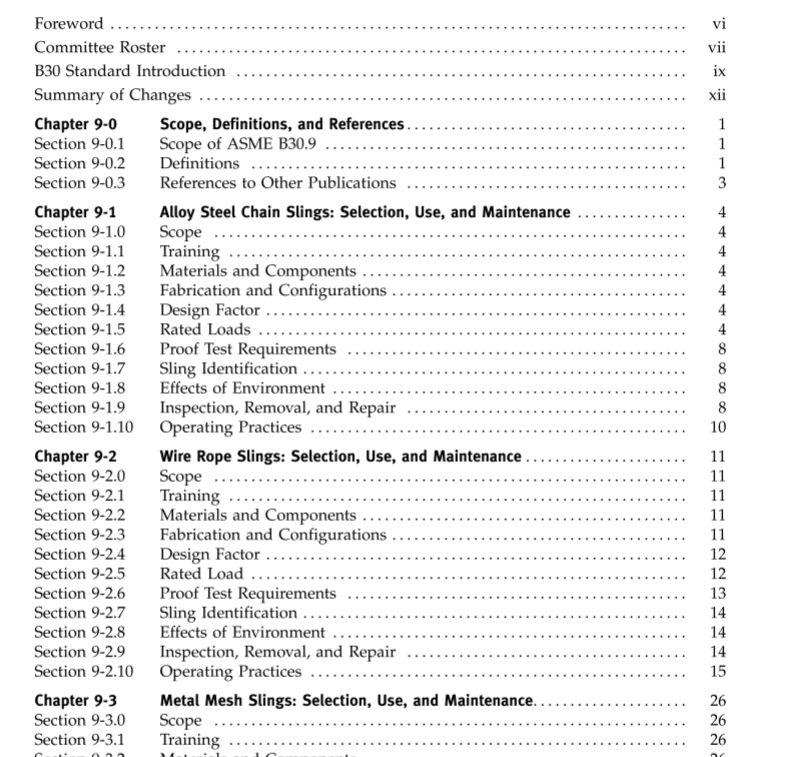

Chapter 9-1 includes provisions that apply to alloy steel chain slings (see Fig. 1).

SECTION 9-1.1: TRAINING

Alloy steel chain sling users shall be trained in the selection, inspection, cautions to personnel, effects of environment, and rigging practices as covered by this Chapter.

SECTION 9-1.2: MATERIALS AND COMPONENTS

9-1.2.1 AHoy Chain

The alloy steel chain shall be manufactured and tested in accordance with ASTM A 391/A 391M for Grade 80 chain and ASTM A 973/A 973M for Grade 100 chain.

9-1.2.2 Components

(a) Components for alloy steel chain slings shall be manufactured and tested in accordance with

ASTM A 952/A 952M.

(b) Makeshift fasteners, hooks, or links formed from bolts, rods, etc., or other such components shall not be used.

(c) Where used, handles shall be welded to the master link or hook prior to heat treating according to the recommendations of the sling manufacturer or a qualified person.

(d) Hooks, when employed, shall meet the requirements of ASME B30.10.

(e) Rigging hardware, when employed, shall meet the requirements of ASME B30.26.

9-1.2.3 Other Materials and Components

Chain or components other than those listed in paras. 9-1.2.1 and 9-1.2.2 may be employed. When such materials are employed, the sling manufacturer or a qualified person shall provide specific data. These slings shall comply with all other requirements of this Chapter.

SECTION 9-1.3: FABRICATION AND

CONFIGURATIONS

9-1.3.1 Fabrication

(a) Grade 80 and Grade 100 alloy steel chain slings shall be fabricated in accordance with ASTM A 906/ A 906M.

(b) Mechanical coupling links shall not be used within the body of an alloy chain sling to connect two pieces of chain.

9-1.3.2 Configurations

(a) Single-leg slings, two-leg, three-leg, and four-leg bridle slings, used in vertical, choker, and basket hitches are covered in this Chapter.

(b) Single- and double-basket slings used in basket hitches are covered in this Chapter.

(c) Other configurations may be used, When used, the sling manufacturer or a qualified person shall provide specific data. These slings shall comply with all other requirements of this Chapter.

SECTION 9-1.4: DESIGN FACTOR

The design factor for alloy steel chain slings shall be a minimum of 4.

SECTION 9-1.5: RATED LOADS

The term working load limit is commonly used to describe rated load.

9-1.5.1

These rated loads are based on the following factors:

(a) material strength(s)

(b) design factor

(c) type of hitch (see Fig. 1)

(d) angle of loading (see Fig. 1)

9-1.5.2

Tables 1 and 2 show rated loads for single-leg vertical, basket hitches, and bridle slings for specific grades of chain. For angles other than those shown in these tables, use the rated load for the next lower angle, or a qualified person shall calculate the rated load.

9-1.5.3

Horizontal sling angles less than 30 deg shall not be used except as recommended by the sling manufacturer or a qualified person (see Fig. 1).

NOTE: Rated loads for basket hitches and bridle slings are based on symmetrical loading. See para. 9-1.10.1(d) for nonsymmetrical loading.

9-1.9.3 Periodic Inspection

(a) A complete inspection for damage of the sling shall he periodically performed by a designated person. Each link and component shall be examined individually; taking care to expose and examine all surfaces including the inner link surfaces. The sling shall be examined for conditions such as those listed in para. 9-1.9.4 and a determination made as to whether they constitute a hazard.

(b) Periodic Inspection Frequency. Periodic inspection intervals shall not exceed 1 year. The frequency of periodic inspections should be based on

(1) frequency of sling use

(2) severity of service conditions

(3) nature of lifts being made

(4) experience gained on the service life of slings used in similar circumstances

(c) Guidelines for the time intervals are

(1) normal service — yearly

(2) severe service — monthly to quarterly

(3) special service — as recommended by a qualified person

(d) A written record of the most recent periodic inspection shall be maintained and shall include the condition of the sling.

9-1.9.4 Removal Criteria

An alloy steel chain sling shall be removed from service if conditions such as the following are present.